Research Project Outline:

Modelling Quality in Spray Drying

| Researcher: | Frank Kieviet (click here for his personal homepage) |

| Advisor: | Prof.dr.ir. P.J.A.M. Kerkhof |

| Group: | Department of Chemical Process Engineering at the Eindhoven University of Technology |

| Project term: | April 1992 - December 1996 |

| Sponsor: | Unilever, Vlaardingen |

| E-mail: | fkieviet@iname.com |

Introduction

Spray drying is a process in which a liquid feed containing a solid

(dissolved or suspended) is sprayed into hot air. The solvent evaporates

and a dry solid in the form of a powder is formed.

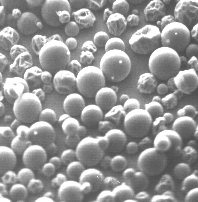

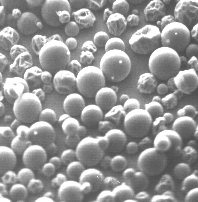

Microscopic photo of spray dried particles.

The particles in this picture have sizes of about 40 microns.

Commercial spray dryers are usually very bulky and expensive. Heights of twenty

meters and more are not exceptional.

When a new product is developed, spray drying tests are done in lab-scale

spray dryers. If the product is satisfactory, the product will be dried in a

industrial plant. The step from a lab scale dryer to a commercial dryer (scale-up) is

very difficult; if the conditions in the big spray dryer are set the same as

in the lab dryer, the product will be totally different.

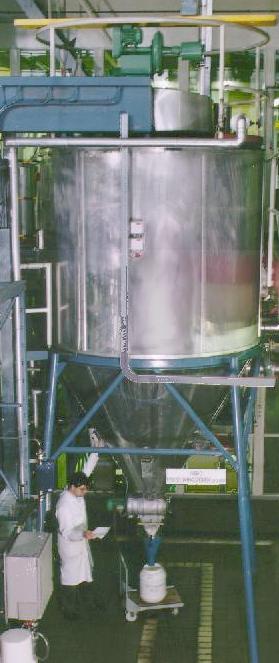

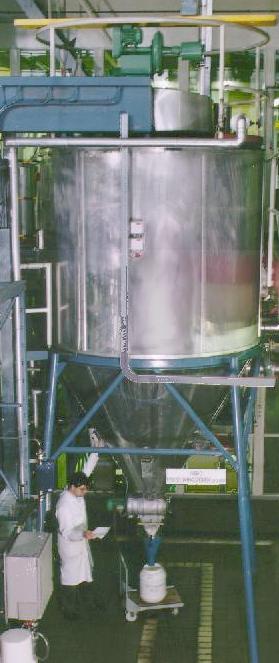

An industrial spray dryer and a lab-scale dryer.

The objective of this research project was to develop models that can be

used to scale up spray drying processes (rather than the scale up of the

spray drying equipment).

Approach

In the scale up of spray drying processes, we have been focusing on product quality.

Typical product quality parameters are moisture content, thermal degradation,

aroma retention and such. These parameters depend solely on the temperature and

moisture history of the particles. In turn, these histories depend on the air

temperature and humidity a particle experiences on its way through the tower.

These histories can be calculated using computational fluid dynamics: starting from

the air flow pattern, the particle trajectories are calculated. Interaction

(heat, mass and momentum) between particles and air are calculated and are added

to the source terms in the flow field calculations. After some of these iterations,

a two way coupled air flow pattern and temperature and humidity profiles is obtained.

CFD calculations of our spray dryer. Leftmost image: the velocity distribution;

middle image: particle trajectories with turbulent dispersion; rightmost image:

temperature pattern in degrees centigrade.

Only half of the tower is calculated (symmetry).

Experimental validation

For the experimental validation, we have a pilot-plant co-current spray dryer to our

disposal.

Geometry of the spray dryer used in this project.

The air flow pattern is measured using a hot wire system (in absence of spray).

Temperatures and humidities in the spray drying chamber are measured using a device

we developed that separates the wet particles from the the airstream that is led to

the temperature and humidity sensor.

Particle temperature and moisture histories are checked using a

temperature-time-integrator. This is a compound (a-amylase) that is added to the

feed of the spray dryer and degrades under influence of increased temperature.

Progress

The project was finished in December 1996. Click here for more information about the

end-report, which was in the form of a PhD thesis.

An outline of the results are:

we have measured the air flow pattern. Due to slow

fluctations, the measurements were not very accurate, but still the agreement of the model

with the measurements was quite good.

The temperature and humidity patterns that were measured, agreed very well with the patterns

predicted with the model.

There is a large discrepancy between the residence time distribution of the particles and

the distribution modelled with turbulent dispesion in CFD. This is caused by the fact that the

particles are deposited on the cone wall, and slowly slide along the wall to the outlet. It is

not possible to model this phenomenon very well.

The thermal degradation measurements agreed not well with the predictions. This is caused

by the residence time distributions of the particles. When these distributions are incorporated

the agreement is much better.

The spray dryer used in this project.